The exposure at this location is approximately 1.5 kilometres, and the main navigation channel into Parry Sound also runs past this unit. Located in Parry Sound Harbour on Georgian Bay, this project was installed to protect the floating docks and launch facilities of the Holiday Cove Marina. It is designed to remain in place in the winter months, and is anchored in place using 6 ton concrete anchor blocks and galvanized chain. This box wave attenuator is a stand-alone system with maintenance catwalks and solar lighting.

The majority of the system is 17' wide, with a short portion of 14' wide units in the shorter fetch direction. Over 1,200' linear feet of floating breakwater was installed. The exposure at this location ranges from 3 to 4 kilometers. Located in Hamilton Harbour, this project was installed to protect the floating docks and launch facilities of the LaSalle Park Marina. LaSalle Park Marina – Burlington, Ontario Where possible, stabilizer finger docks with rigid attachment frames are added to the lee side of the structure, offering additional boats slips while improving the performance of the attenuator. Our floating wave attenuators can also be supplied complete with a wood deck and fascia boards to allow the structure to be used as a combination breakwater and floating dock. At high-energy locations, our exclusive shock-absorbing canisters are utilized in combination with the concrete anchors and chain.

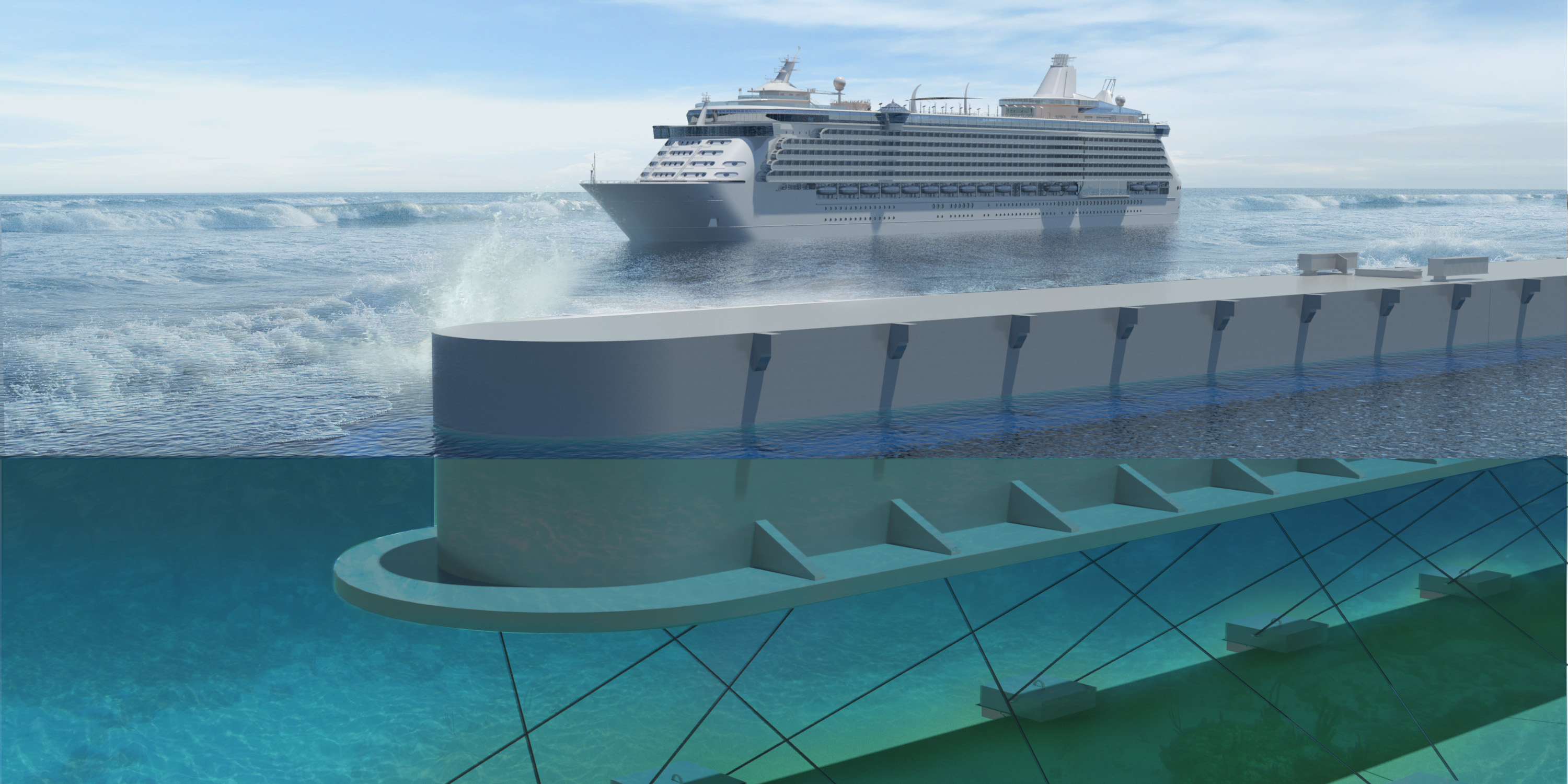

These breakwater structures are typically moored in place with heavy duty galvanized anchor chain secured to massive concrete weights set on the lakebed. Sections are joined together with a high-strength semi-flexible connection system that has been developed through years of experience working in harsh environments. A welded baffle structure is suspended below the float tubes to dissipate and reflect the wave energy, thus sheltering the boats and facilities in the lee of the wave attenuator.Īll steel surfaces are sandblasted and spray-coated with our advanced Devoe "Bar-Rust" epoxy application process for longevity. Our general design concept features large diameter spiral welded steel tubes as the floatation and main structural element of each section.

0 kommentar(er)

0 kommentar(er)